FRESH AIR EVERYWHERE

A leading HVAC supplier can provide pleasant conditions for the entire ship. Koja Marine air conditioning systems improve energy efficiency and passenger comfort. You can trust our HVAC system design, production and commissioning throughout the ships life cycle. We control all conditions on board.

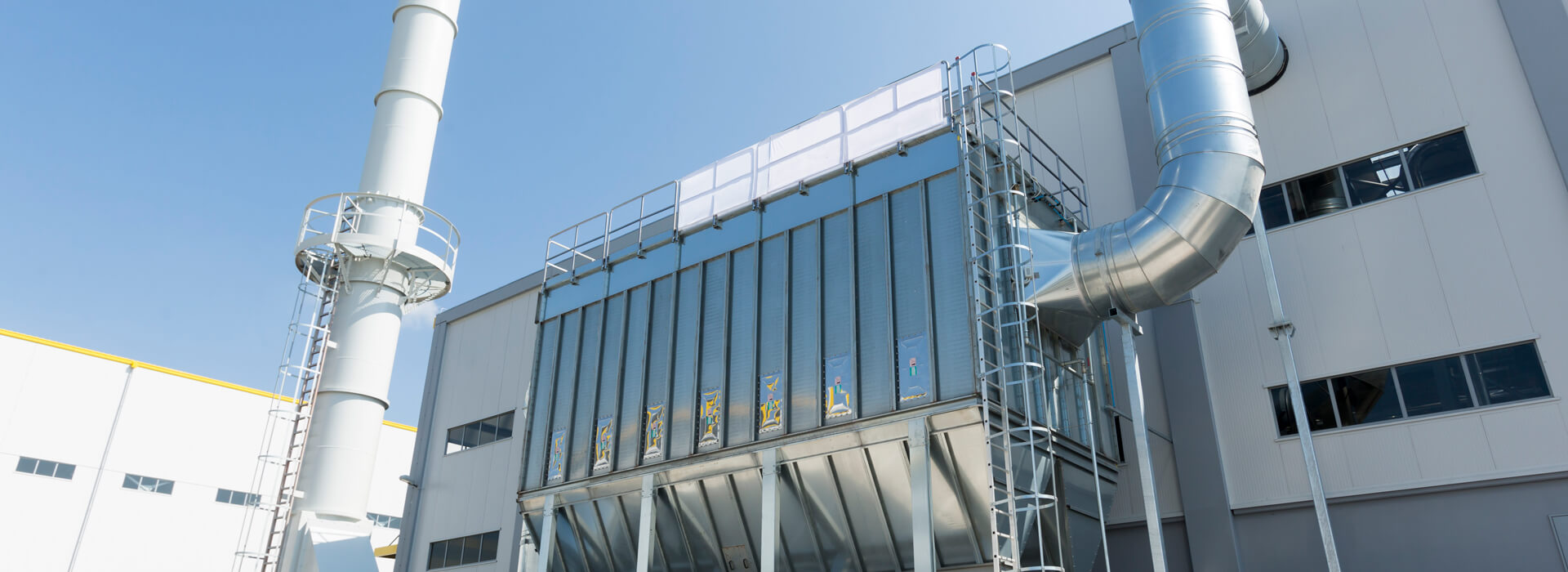

WAVE SOLUTION - SHOW ME THE GREEN

Property sustainability and productivity rise with the same tide. Wave Solution reduces the amount of purchased energy by up to 70% and ensures the well-being of property users.

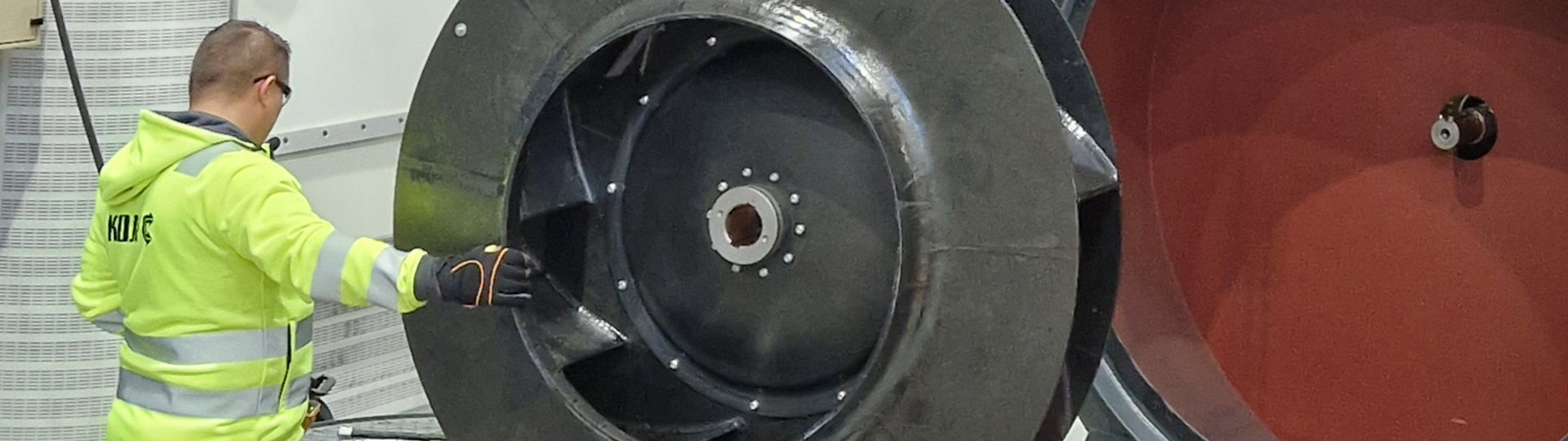

RELIABILITY FROM A SEASONED EXPERT

Koja has delivered reliable and efficient fan solutions since 1935. Our reliable process fans are also energy- efficient – even in demanding processes. Nearly 50,000 fans have been delivered all over the world.